INFORMATIVE

INFORMATIVE

INFORMATIVE

INFORMATIVE

INFORMATIVE

Lamination

Lamination

We carry out the entire production cycle: starting from the lamination of carbon fiber, Kevlar, and glass fabrics, up to the subsequent processes of cutting, shaping, and composition into sandwich panels.

Our production process

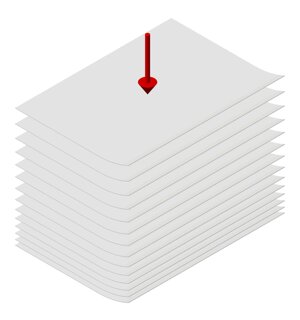

Fabric cutting

The pre-preg fabrics in rolls are laid out and cut with an automated system to the sizes required for lamination.

Milling

The pieces are cut, drilled and milled using a CNC machining center.

Molding cycle

Lamination takes place with a double press system:

First hot press that allows control of temperature, pressure, and the necessary degassing cycles. The maximum operating temperature can reach up to 180° degrees; the maximum operating pressure is between 9 and 13 Kg/cm;

Second cold press with cryogenic system stabilizes and completes the polymerization cycle of the fabric matrices.

SPECIAL APPLICATIONS

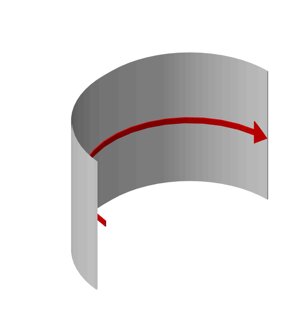

Thermoforming

Hot molding of materials, starting from sheets or film, under pressure or vacuum.

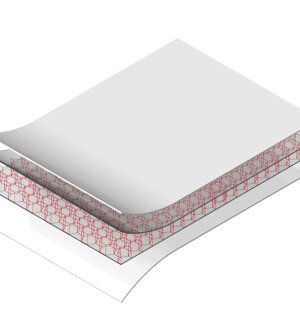

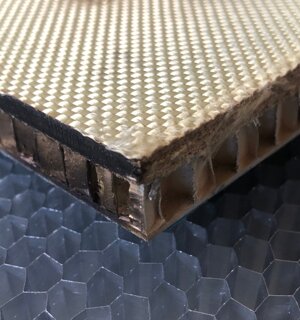

Panel creation

Production of a panel with a support in aluminum or Nomex® honeycomb and one or both skins coated in FIBER-SKIN

Products

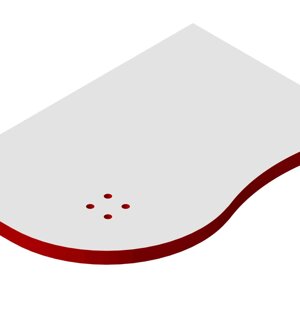

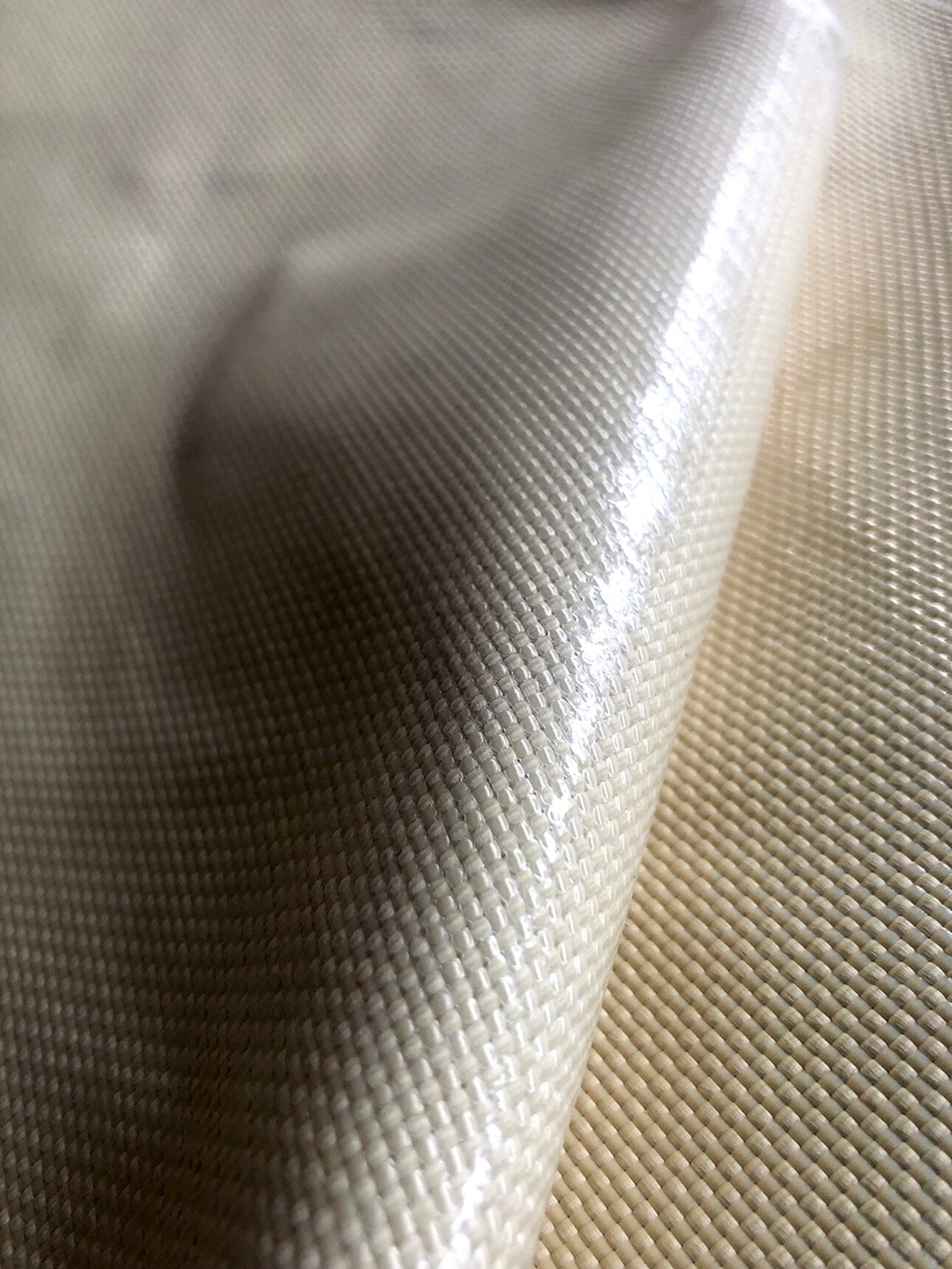

FIBER-SKIN

Lamination of multiple layers of composite fabrics

Creation of a composite skin.

Choice of the type of fabrics, even different from each other, and their number, to be defined based on the desired result.

FIBER-APP

Creation of panel with FIBER-SKIN covering

Production of a panel with a core made of aluminum or Nomex® honeycomb and one or both faces covered with FIBER-SKIN.

Materials

Fabrics

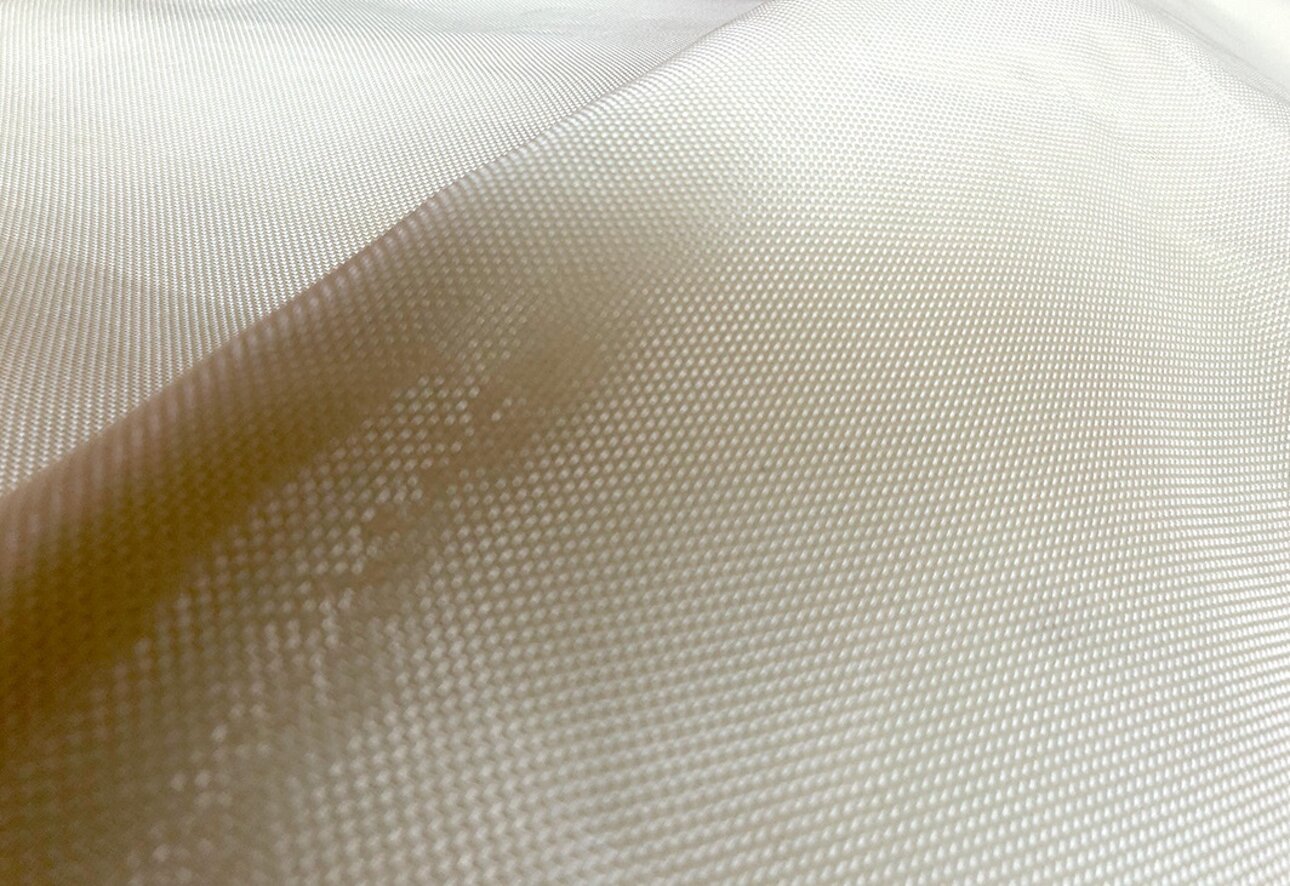

Pre-impregnated fabrics

Pre-impregnated fabrics are made with all compatible types of fabric, from polyester to carbon fiber, through the application of resins, generally epoxy.

Shielding pre-impregnated fabrics

Compared to other pre-impregnated fabrics, shielding pre-impregnated fabrics have an additional “nickel plating bath” that gives the pre-impregnated fabric high shielding properties. These properties provide protection from electromagnetic waves.

Fabrics coupled with polyethylene.

These are dry fabrics coupled with a thermoplastic polyethylene film

Fibre composite

Glass fibers. In structural fabrics, glass fibers are characterized by excellent elasticity, high mechanical strength, and low density.

Kevlar fibers. Kevlar fibers are characterized by remarkable resistance to traction, impacts, and corrosion. In addition, Kevlar laminates are not electrically conductive and are heat resistant.

Carbon fibers. Carbon fibers are characterized by high mechanical strength for the same weight, resistance to chemical agents, and excellent fire-retardant properties.

Polyethylene bonded fabrics. These are dry fabrics bonded with a thermoplastic polyethylene film.

Resins

Thermosetting resins have a non-reversible heat-activated polymerization process. In general, thermosetting resins provide mechanical properties such as low shrinkage during molding, resistance to chemical agents (acids, bases, solvents), temperature resistance, low dielectric constant, and excellent adhesion to metals and fibers.

Thermoplastic resins are characterized by a change of state, from plastic to rigid and vice versa, which can be reactivated by heat. This allows fabrics coupled with these resins to be thermoformed.