INFORMATIVE

INFORMATIVE

INFORMATIVE

INFORMATIVE

INFORMATIVE

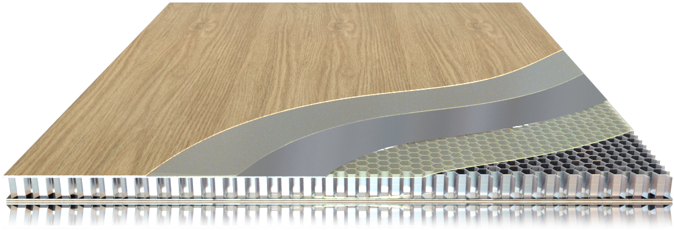

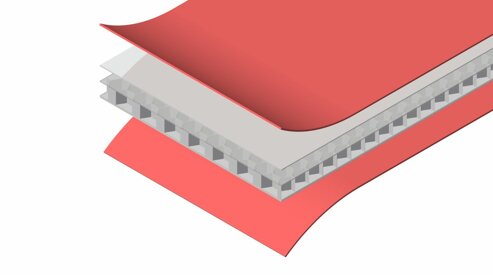

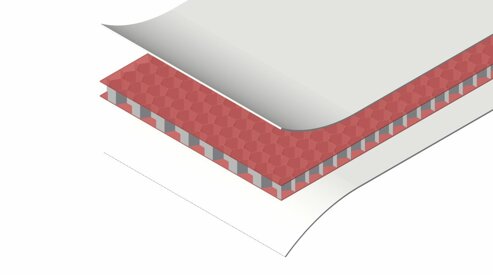

Stratigraphic study

Stratigraphic study

Upholstery leathers

Glue

Structural leathers

Glue

Support

SUPPORT SELECTION

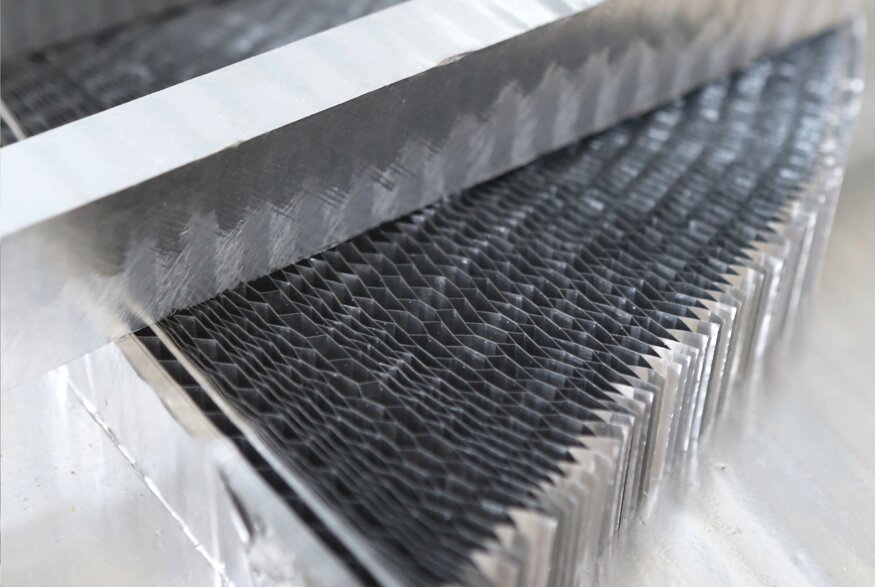

Aluminum honeycomb

Our aluminum honeycomb, depending on the panel application, can be:

- in 3003 alloy with 0.05 mm thickness;

- in 5052 alloy with 0.06 mm thickness;

In aluminum with micro-perforation suitable for air exchange between the cells to avoid a possible detaching effect caused by an increase in air volume due to heat inside the closed cells.

In perforated aluminum on the cell walls to allow the passage of airflow for specific applications that require high vacuum or strong decompression.

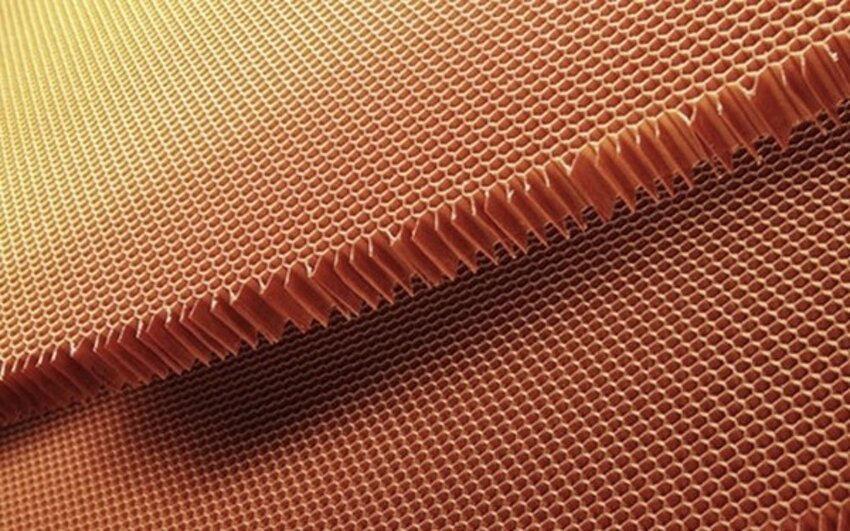

Nomex honeycomb®

The NOMEX® honeycomb is made of aramid paper impregnated with resin, which ensures specific fire and humidity resistance performance as well as resistance to marine salt.

SPECIAL APPLICATIONS

Polyethylene terephthalate

-PET- Polyurethane foams

Polyethylene terephthalate, whose acronym is PET, is a thermoplastic resin belonging to the polyester family, composed of phthalates.

It is also used for its electrical properties, chemical resistance, high temperature performance, and self-extinguishing capability.

The good mechanical properties and FST (fire and smoke) characteristics of the material allow its use in the naval and construction sectors.

It is possible to define:

X

X

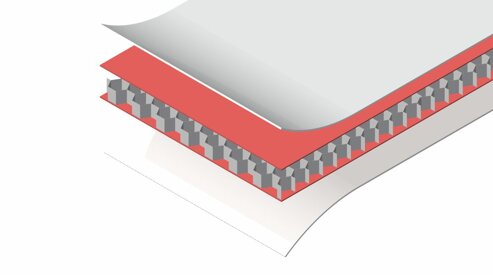

SUPPORT THICKNESS

CELL DIAMETER

The thickness in combination with the cell diameter defines the mechanical characteristics of the panel.

It is possible to produce any thickness on request, from 8 mm up to 60 mm.

It is possible to choose 2 different cell densities.

A higher density increases the mechanical performance of the panel and the resistance to bending with only a slight increase in weight per cubic meter.

ALUMINUM HONEYCOMB

from 3/8 (8.66 mm) corresponding to 40 Kg/mc

from 1/4 (6.25 mm) corresponding to 80 Kg/mc

from 1/8 (3.12 mm) corresponding to 120 Kg/mc

(for panels with reduced thickness or that require

greater resistance to bending)

NOMEX® HONEYCOMB

from 1/16 (3.2 mm) corresponding to a weight of 48 Kg/mc

from 3/16 (1.8 mm) corresponding to a weight of 60 Kg/mc

SKINS SELECTION

The skins can be:

STRUCTURAL in thin aluminum, steel or in composite material in fiberglass, carbon or kevlar

COATING connected to the structural skins to achieve the desired decorative purpose

Structural skins

Structural skins are those surfaces that make up the panel and serve to provide structure and stability to the panel and can be made of:

- Aluminum or metal

- Steel

- G10 fiberglass

- Nomex®

- Kevlar®, one or more layers

To optimize sound absorption or thermal insulation characteristics, it is possible to combine a cork skin with the structural skins

Covering skins

The covering skins are those surfaces that cover the panel, giving it the desired decorative purpose, and can be in:

- High pressure laminate

- Veneer

- Solid wood max 6 mm thick

- MDF

- Glass

- EpoxyPrepreg

Glue

Structural adhesives have different chemical formulations depending on the nature of the materials to be joined:

- Epoxy adhesives for structural use and for bonding composite materials.

- Primers to increase adhesion and surface protection

- Foaming adhesives to seal joints between the same components

- Epoxy adhesive films for bonding surfaces.